3.2

Impact Factor

ISSN: 1449-1907

Int J Med Sci 2023; 20(13):1755-1762. doi:10.7150/ijms.89411 This issue Cite

Research Paper

Custom-made Subperiosteal Implants: A Finite Element Analysis on Monoblock and Dual Implant Systems in Atrophic Maxilla

Istanbul University Faculty of Dentistry Department of Oral and Maxillofacial Surgery, Istanbul, Turkey

Abstract

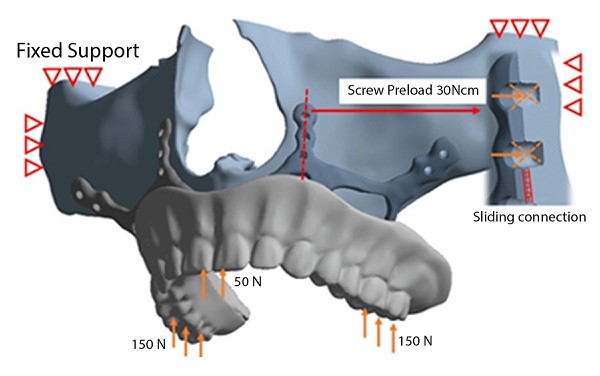

This study aims to investigate and compare the stress distribution, displacement, and bone loading of monoblock and dual custom-made subperiosteal implant systems in atrophic maxilla using finite element analysis (FEA). A total of 11 patients with insufficient bone tissue for conventional implant treatment were included in the study. Customized subperiosteal implant designs were generated using the 3D average models obtained from patients' computed tomography (CT) scans. Two different models were produced: a monoblock that covered the entire maxillary bone and a dual implant system where two mirror-imaged implants covered the left and right halves of the maxillary bone separately. We have calculated residual stress values formed on the implant models and jaw bone models separately. In addition, the highest displacement values formed on the implants and the highest stress values formed on abutment parts have also been observed in this study.

Results showed that the stresses formed on implants that are under the mastication forces were significantly lower than the yield strength of the selected material, indicating that plastic deformation would not occur under static load. The dual implant geometry demonstrated a substantial reduction in stress compared to the monoblock structure. The highest von Mises stress values for the monoblock implants ranged from 131 MPa to 206 MPa, while those for the dual structure ranged from 124 MPa to 178 MPa. The highest residual stress values on the upper jawbone were observed in the M6 implant model, and the lowest was seen in the M1 and M3 models at 12 MPa. Displacement values under static load showed that loads on the implant would be below 0.21 mm.

In conclusion, custom subperiosteal implants are a viable treatment option for patients with insufficient bone tissue for conventional implants. Dual implant systems were found to have lower stress and displacement values compared to monoblock structures, indicating a potential advantage in clinical use. However, mono implants may have benefits in cases of immediate teeth loading due to their ability to absorb and distribute occlusal forces better.

Keywords: Custom Made Implant, Subperiosteal Implant, Severe Bone Resorption

Global reach, higher impact

Global reach, higher impact